Nanolum

Advanced Metal Matrix Composites for Extreme Performance

Exceptional EMI Shielding

Exceeding standard requirements for a wide range of frequencies.

High Strength & Ductility

Aluminum matrix reinforced with nanoscale ceramics.

Lightweight & Recyclable

Pure aluminum matrix – 100% recyclable

Customizable Fillers

Custom ceramic compounds for optimized shielding and strength.

Applications

Nanolum's aluminum composites integrate high strength, low weight, and tailored electromagnetic/radiation protection into a single material.

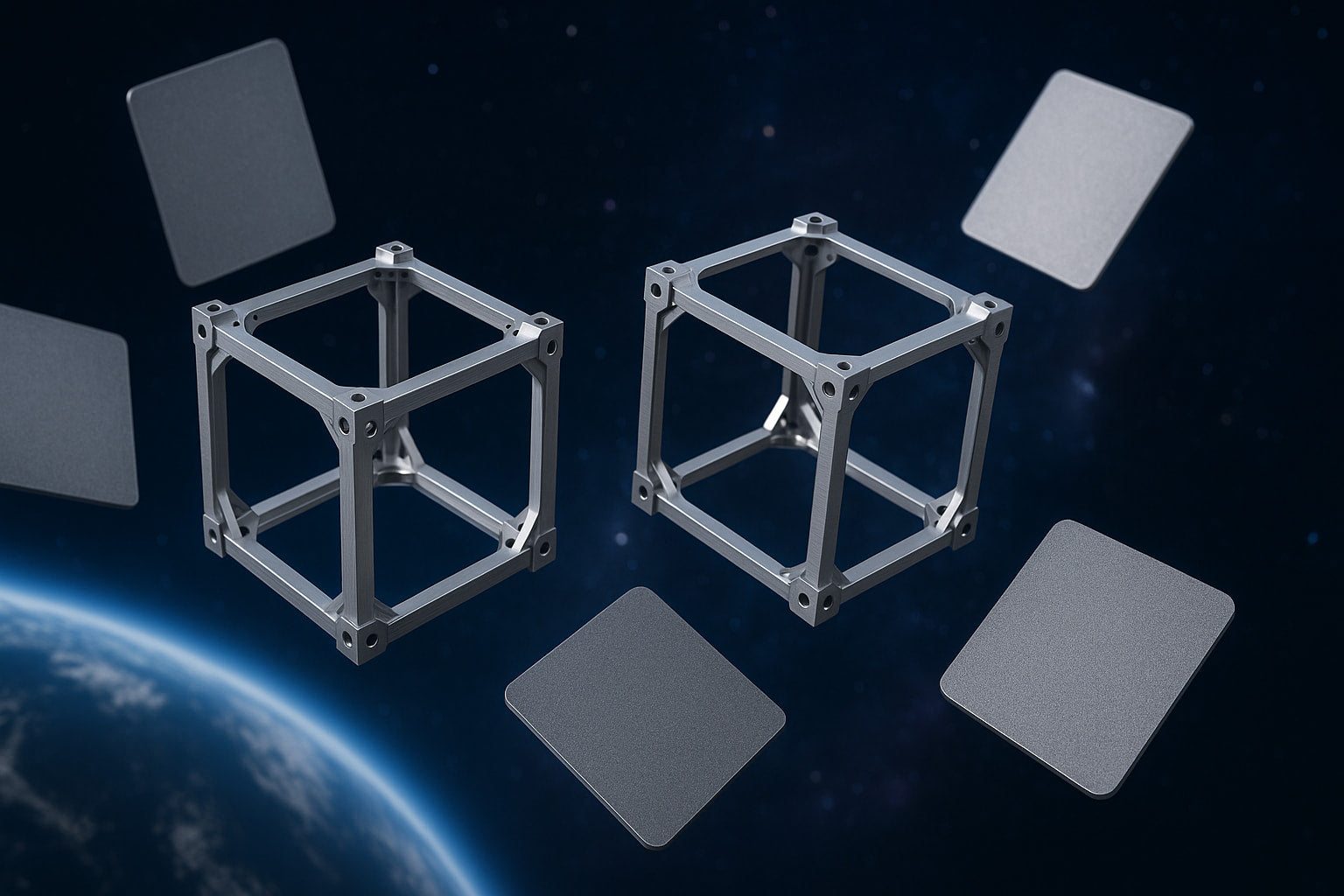

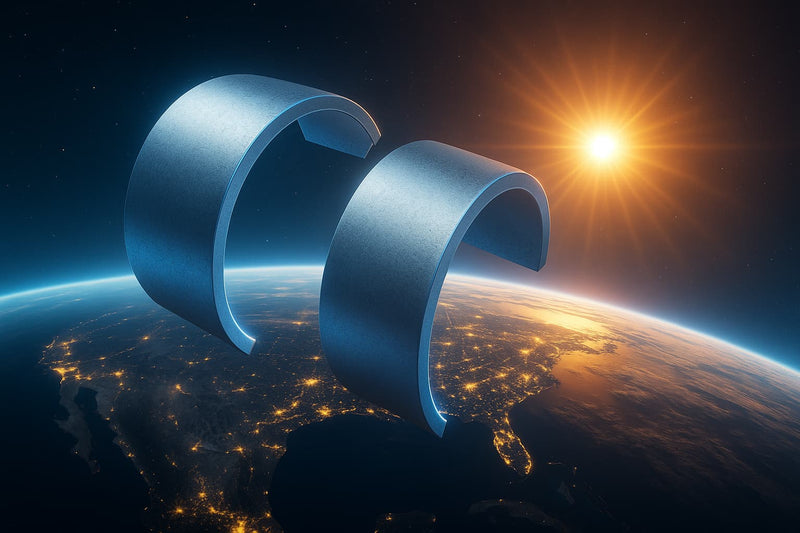

Cube satellites frames and shielding panels

Challenge

CubeSats must withstand extreme launch stresses while keeping payload mass to an absolute minimum. Traditional shielding adds weight and complexity.

Solution

Nanolum’s ultra-light aluminum MMC frames and panels deliver high stiffness-to-weight ratios with engineered fillers that provide both EMI and radiation shielding.

Benefit

Onboard electronics are protected from space radiation and interference without the need for multilayer shielding—reducing mass, saving space, and improving mission reliability.

Drone electronics shielding enclosures

Challenge

Drones operate in environments where electromagnetic interference—including deliberate microwave or RF pulses—can disable flight controllers, sensors, and communications.

Solution

Nanolum’s lightweight, high-strength enclosures offer superior EMI shielding effectiveness while maintaining thermal management and durability.

Benefit

Sensitive electronics are safeguarded against electromagnetic threats without compromising flight endurance, payload capacity, or maneuverability.

Low-frequency EMI shielding

Challenge

Power electronics, radar systems, and other technologies generate low-frequency magnetic fields that are difficult to block with conventional materials.

Solution

By integrating fillers such as mu-metal or ferrites into aluminum MMCs, Nanolum achieves strong low-frequency EMI attenuation while retaining machinability and corrosion resistance.

Benefit

Customers gain reliable low-frequency shielding in components that remain lightweight, durable, and easy to manufacture.

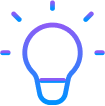

Small Modular Reactor (SMR) shielding

Challenge

SMRs require structural materials that can both withstand high thermal loads and attenuate neutron and gamma radiation, all within compact geometries.

Solution

Nanolum’s composites integrate high-Z boride fillers into an aluminum matrix, creating dual-purpose materials with structural strength and built-in radiation shielding.

Benefit

A single component can serve as both structure and shield, simplifying design, reducing system complexity, and improving overall safety margins.

Solutions

Advantages of using Nanolum’s composites

- Challenge: Traditional aluminum is lightweight and easy to machine, but lacks the strength and shielding capabilities needed in today’s aerospace, defense, and energy applications. Conventional multilayer shielding adds weight, complexity, and cost.

- Solution: Nanolum’s aluminum metal matrix composites (MMCs) combine aluminum’s corrosion resistance, thermal conductivity, EM reflectivity, and machinability with engineered reinforcements. Using advanced powder metallurgy, we uniformly disperse nanoceramic and other fillers throughout the matrix.

- Benefit: The result is a recyclable, cost-effective composite material that has good mechanical properties and is customizable for each application. One material can provide both structure and shielding, eliminating multilayer systems and enabling lighter, more efficient designs. In particular, the nanoceramic reinforcement significantly decreases the reactivity of fine aluminum powders, making the powdered composite safer to handle.

The "fillers"

- Challenge: No single material can block every type of interference. High-frequency EMI, low-frequency magnetic fields, and ionizing radiation each require different shielding strategies.

- Solution: Nanolum tailors its composites by incorporating fillers sized from the sub-micron to micrometer scale. Options include high-permeability alloys like mu-metal for low-frequency fields, conductive particles like nickel-coated graphite for high-frequency EMI, and high-Z borides or ceramics for neutron and gamma radiation. Multiple fillers can also be blended into a single composite for multifunctional protection.

- Benefit: Designers gain the flexibility to target specific threats—or multiple threats simultaneously—while maintaining lightweight performance and structural integrity. Each composite is engineered for the customer’s unique environment, whether in space, air, or nuclear systems.

The "shielding effect"

- Challenge: Sensitive electronics and structures face threats across a broad spectrum—from disruptive RF signals to harmful ionizing radiation. Traditional shielding often requires separate layers, adding bulk and complexity.

- Solution: The shielding effect in Nanolum’s MMCs comes from the uniform distribution of engineered fillers within the aluminum matrix. These fillers absorb, deflect, or attenuate electromagnetic waves and radiation at the source. By adjusting filler type, concentration, and enclosure thickness, we can fine-tune composites to meet or exceed shielding standards across multiple domains.

- Benefit: Customers receive a single material that serves as both structure and shield. This integrated approach streamlines design, reduces overall mass, and ensures reliable protection against EMI and radiation threats—all without compromising machinability or durability.

Technologies

Advanced Aluminum Composites Engineered for Performance and Safety

Products

Powdered composites

ProductPre-compacted ingots

ProductExtruded profiles or forged shapes

ProductResearch Projects

Customized composites

CustomizationReinforcing third-party powders

CustomizationOur Company

Vision

Nanolum envisions a future where cost-effective aluminum composites provide superior structural and shielding properties in a single, integrated material system.

By enabling multifunctional protection without added mass or complexity, Nanolum’s materials support safer, more efficient, and more sustainable designs for mission-critical industries.

How we innovate

Nanolum has developed a proprietary, cost-effective powder metallurgy process that uniformly disperses ceramic and metallic fillers within an aluminum matrix. This process is highly versatile, allowing for different aluminum alloy powders—or even other metals—to be enhanced with tailored reinforcements.

Customers receive composites with reliable, repeatable properties and mission-specific performance, whether the application demands EMI shielding, radiation attenuation, or enhanced structural strength.

Quality assurance

Nanolum implements stringent quality assurance protocols, including scanning electron microscopy (SEM) for powder inspection and a combination of SEM and ultrasonic attenuation measurements for full-density products. Customers can trust that every Nanolum composite meets exacting standards for microstructure, uniformity, and integrity—ensuring reliable performance in the most demanding environments.

Get in Touch

We'd love to hear from you. Send us a message and we'll respond as soon as possible.